PIT DESIGN

PIT DESIGN

HEIGHT AND WIDTH OF BENCHES IN OPENCAST MINE

1.In Alluvial,

soil, morum, gravel, clay, debris ( soft over burden), the sides shall

be sloped at an angle

Of safety not

exceeding 45 degree from the horizontal or at an angle Regional inspector

permit.

Kept benched at ht. not exceeding 1.5 m and

width shall not be less than ht.

2. In coal sides shall

be sloped at an angle of safet not exceeding 45 degree from the horizontal or the sides

shall be kept benched not exceeding 3 mtr. In ht..

IN MECHANISED MINE

1.A.Ht.of bench

shall not exceed the maximum reach of m/c used for digging, excavation and

removal.

incase of uniformly soft rock the regional

inspector may permit the extension of the ht. up to 3 mt. above

the digging ht. of the m/c.

B. Width of any bench

shall not be less than

§Width of

any m/c plying on the bench plus 2 mtr.

Or

§If the

dumper is plying on the bench 3 times the width of the dumper.

Or

§Twice the plan length of excavators like shovel and

twice the length of body of m/c like dragline

whichever is more.

Provided that where

dragline used the width of any bench

below in coal /overburden at the finishing stage shall not be less than 3 mtrs.

or

§the ht.

of the bench whichever is more.

§Safety

precaution – when persons are employed within 5m of the

working face adequate precaution shall be taken to ensure their safety by

dressing .

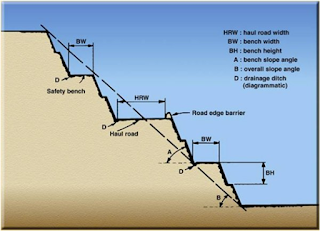

HAUL ROADS

Haul

road is life line in the operation of any opencast mine.

Parameters

for good haul road;

vShall

be to provide one way traffic. Where it is not

practical width shall not be

less than 3 times the width of any m/c plying on the road.

vCorners and bends shall be such that it shall provide

clear view for a

distance of not less than 30mtr. along

the road.

vwhere it is not practicable there

should be separate

two roads for up and down

traffic.

vAt curves super elevation shall

be provided according to speed of the vehicle.

vNo

road shall have gradient less than 1 in 16 at any place.

vRamp over small stretches shall have gradient

up to 1 in 10.

vWhere

any road exist above the level surrounding area , it

shall have

a strong parapet walls or embankments not less than 1 mtr

ht.

v Road

signs shall be provided at every turning points for the guidance of the drivers.

vAt

every curve , parapet walls or vertical posts Zebra lines shall be provided

vThe

portion of surface haul road in mine premises where there is heavy

traffic of men and machines should have separate

lane properly fenced off from the haul road for pedestrians and two

wheelers.

vStandard

traffic signs shall be displayed at conspicuous places alog

the haul road.

v road

surfaces shall be maintened smooth and of sufficient strength.

vLoaded

trucks and dumper shall not reverse on gradient.

vA berm at

least half the diameter of the wheel of the largest dumper plying or one meter

whichever is greater and of adequate width provided at the edge of the spoil or

coal dump.

Small vehicle shall not be

allowed on the haul roads.separate road shall be provided at

For the small vehicle.

Only authorized vehicle shall be allowed

With raised red flag

in the daytime and redlight in the night.

The flag or light shall be visible for the dumper

operator from a distance

Of at least 30m.

Stander of

illumination-Roadways and footpath from bench to bench – minimum standard of

illumination 3 Lux horizontal.

Factors responsible for slope failure

vSlope

angle

vGeo

mechanical properties of slope materials.

vPresence

and orientation of faults and other discontinues.

vPresence

of water.

vDepth of

the pit.

vEffect

of blasting.

vPresence

of u.g. working.

vPresence

of fire

vPresence

of week bed in the OB

vUndercutting

or toe cutting

v

PROBLEMS ACCOCIATED WITH

HIGHWALL

1.Because of

jointing , slabbing etc.

probability associated with

Slope failure increases.

2.It will require deep

hole blasting with heavy amount of explosives.

Which will produce

vibration, fly rocks, boulders air blast etc.

3.Because of slope

failure or boulder falling from the top ,severe damages of machineries

And serious accident to

persons.

4.Supervision is

difficult.

5.Water pressure in the

joint responsibility for more frequent slope failure.

6. Problem of floor

sliding due to presence of aquifers.

Precaution-

1.Angle of

slope of the bench should be equal or less than angle of repose of the bench

rock. For dragline bench angle of slope of the high wall benches varies from

70-80 deg.

2.Face

should form an angle with the main cleats, fractures etc.

3.Bench dose

remain for long time, quick rate of advance.

4.Controlled

blasting should be practiced..

5.Highly

charged water bearing strata should be dewatered by putting boreholes with

pumps.

6.Weak plane

in the strata should be cement groued.

7.Bench ht.

should not be more than required.

8.Design and

review shall be done by experts from

CMRI,CMPDIL etc.

9.Undercutting

and toe cutting should be avoided.

EFFECTIVE DRAINAGE

1.The quarry should

provided with effective garland drains.

2. The benches should have effective toe drains.

3.Stablity may be improved

by effective drainage of the slope . Horizontal holes are drilled in to the

slope face for effective drainage &

to reduce water pressure. Holes are drilled at angle of 5 degree will facilitate

free flow of water. Holes may be 10-15 deep at intervals of 5m or less. A pipe

inserted in to the hole to prevent caving. The pipe should be perforated.

SPOIL BANK

1.Slope of spoil bank face shall be determined by the natural angle of

repose of the material, but shall not in no case exceed 37.5 degree from the

horizontal.

2.The

spoil bank face shall not be retained by artificial means at an angle in excess

of natural angle of repose. Any spoil bank exceeding 30m in ht. , should be

benched so that no bench exceed 30m ht. and general slope does not exceed I1 vertiacal to

1.5 horizontal.

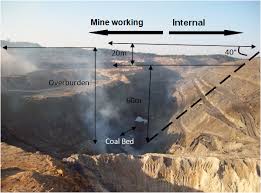

3.Incase of working by dragline ,where the inclination of the bed rock does not exceed 5 deg. From the

horizontal, the ht of

overburden dump shall not exceed 60m.A bench of 10- 15m wide in overburden

overburden shall be maintained between these dumps and final dump created by

the dragline. If the inclination of the bed rock exceeds 5 deg., the ht. of the

forebank

shall be suitably planned.

3.The toe of the spoil bank

shall not allowed to reach a railway or other public works or other public

roads or building or other permanent structure not belonging to the owner of

the mine closer than a distance equal to the vertical ht. of the

face.

4. A suitable fence

shall be erected between any roadway or public works or road or building or

structures and toe of the active spoil bank at a distance of not less than ht of the

spoil bank.

5.No persons shall

be permitted to approach near the toe of

an active spoil bank.

6. The manager shall

appoint the sufficient no. of competent persons to supervise dumping operation.

7. The manager shall

formulate Dumping rules which shall specf

y

a.The

provision of system of drainage

b.System of inspection

c.Maximum

ht. of the bench. The ht of the shall not exceed 60m .

8.

ReplyDeleteonline marketing companies in hyderabad

At Tech Sprint Innovations, we are a top online marketing companies in hyderabad, including web design, SEO, social media marketing, Google Ads, content creation, and more. Our expert team helps businesses grow by driving engagement, generating leads, and maximizing online presence. Innovate. Optimize. Succeed.

online marketing companies in hyderabad

Benching Meaning in Relationship?

ReplyDeleteBenching refers to the act of keeping someone as a romantic or emotional backup while actively pursuing other dating options. The term is a metaphor derived from sports—where a benched player isn’t actively participating in the game but remains on standby in case they’re needed.

In dating, it looks like this: someone expresses interest, maintains just enough communication to keep the other person “on the hook,” but never fully commits. You might receive a “Hey stranger” text once a week or get vague promises of plans that never materialize.

Benching Meaning is not ghosting (where contact is cut off entirely) or breadcrumbing (where tiny bits of attention are dropped). It’s a more calculated and emotionally manipulative practice.