ABOUT BLASTING

BLASTING – It is technique in which , solid rock mass

is brought in to small by

using explosives.

Explosives- It is a solid or liquid substance or a

mixture of chemical substance

which is converted instantaneously in to Large volume of gases at high temperature and pressure when

subjected to combustion or detonation. chemical energy is converted in to mechanical

energy which is used

to break the rock masses in to small pieces.

Detonation- it

is a process of giving sufficient violent shock to the explosives or it is a

process of propagation of shock wave through an explosives.

Types of explosives

Low explosives & high Explosives

•Strength-Amount of

energy by an explosive during blasting.

•Velocity

of Detonation-Rate at which detonation wave passes through a column of

Explosive . More the intimate contact between oxidizer and fuel , higher will

be the VOD.

•Density- High density

explosive required for blasting in hard rock in tunneling in hard ground. Low

density explosive is required when lump coal is required and

in soft rock like coal.

•Water Resistance-Explosive

deteriorate under water and moisture penetration.

•Sensitivity-

An explosive is required to be insensitive to normal handling , shock and

friction.

•Fume

characteristics-Explosives must produce minimum of harmful gases.

•Legal

permission- In underground mine only permitted type explosive must be used.

Ingredient

of explosives:

vCombustible matter

wood meal, fibre, sulpher , charcoal etc.

vOxidizing Agent- sodium nitrate, potassium

nitrate, ammonium nitrate, etc.

vStabilizers such as

magnesium and calcium carbonates .

vAn tisetting agent to prevent setting of salt.

vSensitizers like

metallic powder like aluminum powder.

Low Explosive-

• Is blasted through the process of oxidation of the constituent

particles by rapid combustion From particle to particle through mass

of explosive.

•Effect of explosive is

relatively Low.

•Fired

by ignition or a flame.

•Produce heaving

effect.

•Gun

powder, propulsive compound for fire work.

HIGH EXPLOSIVE

vContain ingredient

which itself is explosive when sensitized by proper mean.

vExplodes when a

violent shock is applied to it with the help of a detonator

vOxidation takes place

instantaneous with high velocity of reaction.

vProduce shattering

effect.

vAN, ANFO, nitroglycirine, TNT, special gelatine, slurry explosive

etc.

v

GUN POWDER- Charcoal 15%, sulphur

10%, Potassium Nitrate 75%. Low

explosive.

vNon of its

constituents is explosive.

vHas heaving effect.

vHygroscopic, loose

explosive power when damp.

vProduces flame of long duration.

vThe explosives is

fired by safety fuse.

vNot used in underground coal mine

Nitroglycerine

: Oily fluid, Sp. Gr. 1.6,feezing point

13 0 c, insoluble in water,

vVery sensetive to explosion by shock of any nature. Seansivity increases with

freezing.

vSo to make it suitable for industrial

use it must be absorbed with some inert material or gelatinised.

vIt is available in three consistencies-gelatenious, semi gelataneous and powdery.

vHas shattering effect

vProduce fumes which produces fumes which causes headache after long exposure.

vLow freezing agent usually Di Nitro glycol which is itself is

powerful explosive is mixed to

vLower the sensivity to detonation.

vLow freezing explosives are designated

as Polar – polar viking,polar special gelatine etc

AMMONIUM NITRATE: White hygroscopic salt

vVery soluble in water, safe to handle

vIt canbe

detonated by a booster of high explosive. It is difficult to detonate by itself

and by a detonator. Non capsensetive

vTo use it sa a explosive it is mixed with diesel oil,N.G., or TNT.

v@NH4NO3=4H2O+O2+2N2 +346 Kcal/gm.

v

Collodion cotton - reaction between

cellulose compound and nitric acid yeilds Colllodian cotton.

TNT- Reaction between nitric acid and benzene or tolune compound yeilds Trinitrotolune

T.N.T.

Booster- For effective

detonation of some slluary, AN-FO mixture high

detonating velocity booster is used . Indian explosives LTD. manufacture a booster with

trade name PRIMEX. It is cast as cylindrical pallets with two longitudinal holes

for threading on to down line of detonating fuse for priming a detonating fuse is threaded

through two holes and a knot is tied at the top.

This assemby is inserted into

slurry explosive cartridge and its mouth is retied at the top. After lowering

the primer cartridge other cartridge are lowered.

Primex

pallets are also lowered down the hole , threaded through the detonating fuse

at regular intervals throughout the slluary

column.

The recommended interval are Above

150mm.dia.- one 500gnm pallets every 7-8 cartridge. In 150mm.dia.-

one 250gm

pallets

every 5-6

cartridge. 83/100mm.dia.- one 100gnm pallets every 10-11 cartridge for Powerflow -3

and similar explosives.

PRIMEX a mixture of PETN and TNT. Water

resistance , VOD 7000m/s. wt. strength 82, detonated by detonating fuse of

detonator.

Booster manufactured by IDL chemical limited - PENTOLITE

Following can be used as primer or booster.

Gelatanious NG based explosives can be used .Example – O.C.G. or

special gelatine,

Slurry explosive such as indoprime ,Aquadyne ,and superdyne also served as booster.

ANFO- Ammonium nitrate fule oil explosive – Ammonium nitate mixed with diesel

oil .

Most balance oxygen balanced explosive is one with 5 to

6 % of diesel oil with wt.. Excess amount of diesel oil lower sensitivity to

initiation of the explosives.

Sp.gr. .8 to 1.wt.strength 75-80 , VOD 3500 m/s .

Non capsensetive and initiated by small quantity of O.C.G. or by a

booster.

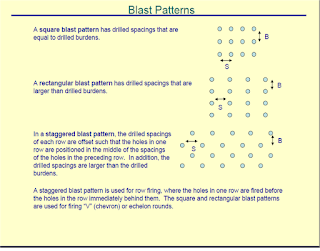

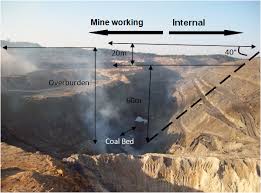

Burden- It is the shortest distance to relief at the time the

hole detonates. Relief is normally considered either a ledge face Or the internal face

created by a row of holes that have been previously shot on an earlier delay.

Lower burden is required for hard rock.

If burden is too small , rock is thrown

a considerable distance from the face, air blast level is high, fragmentation

is fine.

If burden is too big

severe back breake occurs behind the

last row of the holes

Fly rocks

Ground vibration

Boulders formation

Bottom or toe problem

Burden=20 to 35 times the hole

diameter. Max. 50 times the hole diameter.

Burden=within 40- 55% hole depth

Burden B in ft.=0.67 De (Stv/Sgr)

De=Dia. Of explosive in inch

Stv=

relative bulk strength

Sgr= specific gravity of the rock

Blast hole diameter- Dia of

blast hole depends upon bench height, type of Rock, fragmentation required ,

acceptable vibration level, fly rock, and location of blast site .

More the bench ht. larger the hole

diameter.

Hole diameter is

generally kept H/40 TO H/60. H= depth of the hole in meter.

Two

general conditions for initiation

timing

Blast holes can be fired near simultaneously or

fired delayed from one another.

Simultaneous initiation in a row require larger blast hole

spacing than firing on delay, also

Produce increased ground vibration (

many holes in a row fired simultaneously), formation of boulders

Will also take place.

Delay timing reduces ground vibration

and produce fine fragmentation.

Hole to hole delay along a row t = T * S , T= delay const.,S= spacing in ft.

Hi! I read your blog. Its so nice.EXPANDO is an expansive mortar chemical that cracks rocks and concrete. It is a concrete cutting, granite breaking and general demolition solution. This non-explosive demolition agent is easy to use, cost effective and a safer option for silently breaking up hard materials like rock or concrete. Simply drill, mix and pour.Non Explosive Demolition Agent

ReplyDeleteI really appreciate the efforts of the writer as every single sentence is written very carefully. I was looking for a hassle-free Fume Extraction Systems and I got it from Clear Ion Experts. Just read this post and know more.

ReplyDeleteIf You Also Looking for a Fume Extraction System for Welding then MECHVAC Engineering is the best option for you. Here We Provide the Fume Extractor for Welding, Welding torch MIG, and MIG welding gun. We also provide the on-gun Fume Extraction System.

ReplyDeleteDust Extraction Installation

Welding Air Filtration Systems

Industrial Air Conditioning Adelaide