ENVIRONMENTAL EFFECT OF MINING

Environmental Impact of Mining -The environmental

impact of mining includes

• loss

of biodiversity(flora &fauna), and

• contamination

of soil, groundwater and surface water, air, noise & vibration.

Also

affect the health of the local population.

In

areas of farming it may disturb productive grazing and crop lands.

Impacts on

Ecology:-

1.Removal of

all vegetation (flora) and thereby fauna from the area required for mining.

2. Pollution

of water in the surrounding water bodies, This affects the aquatic ecology of

these water bodies.

3. Dust in

atmosphere, when deposited on the leaves of the plants in the surrounding areas

may retard their growth.

4. Noise and

vibrations drive away the wild animals and birds from the nearby forest.

5. Water

scarcity due to the impacts of opencast mining on water regime affects the

growth of vegetation and agriculture in and around the complexes.

Impact on Land :

Due

to Large scale excavation. Removal of topsoil sub soil.

Dumping

of of solid wastes. Creat derelict(negletful) land.

Subsidence.

Effect on agriculture.

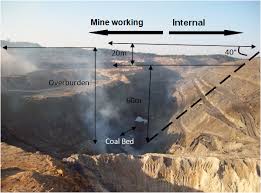

Impacts on Land:-: :- Impacts of opencast mining:-

Topography and land scenario changes

The

land-use in the surrounding areas may get affected due to the impacts of mining

on water regime.

In

the mines having mineral concentration it is required to make tailing dams to store

the tailings from the concentration plants.

These

dams need land and may cause pollution of nearby underground and surface water

sources.

The

drainage pattern on the surface undergoes a change.

: Impact on Atmosphere:- Impacts of opencast mining :-

Due to use of HEMM, BLASTING ,FIRE, DIESEL & PETROL VEHICLES and other

mining activities

Production

of dust in atmosphere.

Increase

in sox,nox,co,co2 etc in atmosphere.

Affect health of people, Global warming.

All

the surface water bodies have to be removed .

All

the aquifers, including the water-table

above the mineral deposit are damaged .

If

there are high pressure aquifers below the mineral deposit it becomes necessary

to pump out water from these aquifers .

Water

in the nearby water bodies gets polluted .

In

the areas having pyrites and sulfides in the rock mass the mine water as well

as the leaches may be acidic and their discharge in the surface water bodies

may enhance heavy metal pollution potential.

Impacts on Water Impacts of Mineral

preparation:-

The

effluents from the mineral preparation plants when discharged into the surface

water bodies, pollute their water.

The effluents when discharged on the surface pollute the

top soil and sub soils and also the water table.

What is Noise Pollution?

Noise pollution (also sound pollution, sound disturbance)

refers to the excessive and troublesome sound that is injurious to health.

Noise pollution refers to the presence of such levels of

noise or sound in the environment that are disturbing, irritating and annoying

to living beings.

SOURCES

• BLASTING

• OPERATION

OF HEMM,CHP,etc

Effects of Noise Pollution

1. Loss

of hearing and deafness:

2.

Cardiac disturbance:

3.

Sleeplessness:

4.

Headache:

5.

Stress, tension and aggressiveness: .

6.

Irregular blood pressure: .

7.

Mental imbalance and nervous debility:

8. Psychological imbalance: It may also cause psychological imbalance.

8. Psychological imbalance: It may also cause psychological imbalance.

9.

Difficulty in talking:

Administrative –

supplying the workers being exposed to

occupational noise exceeding 87 dBA with earplugs,

semi-insert

plugs, muffs and helmets, –

reducing hours of work where excessive sound

pressure levels are experienced,

–

task rotation of workers, –

training the workers about the use of personal

protectors and explaining their advantages, –

having

the mine workers undergo periodic medical inspections to check hearing.

Engineering noise controls

– selecting the processes with lower sound

pressure levels,

–

locating the mine-related plants in noiseless places,

– enclosing the source of noise and preventing

the noise from being transmitted,

– isolating the operators’ cab,

–

moving the noisy machine to a little

-used section of a mine.

Noise

level

• 85 dB(A) warning limit

• 90 dB(A) danger limit

• A person shall not be allowed

without appropriate ear protection in an area where noise level is 115dB (A)

• Personal protective equipment shall

be worn if there is single isolated outbrust of noise above 130 dB(A) impulse

or 120 dB(A) fast

No

person allowed in 140dB(A) nose

NOISE

.

Control

• Use

of ear muffs/earplug/helmets

• Improve

design

VIBRATION- SOURCES

• BLASTING

• OPERATION

OF HEMM, CHP,etc

CONTROL

• CONTROLLED

BLASTING TECHNIQUES

• IMPROVE

MACHINE DESIGN

Control of Ecological Impacts:-:

Plan

the mining layout so as to have the least requirement of the forest land .

Develop

a suitable compensatory forest.

Develop

a flora bank to preserve the typical floral species.

The

noise and vibration producing activities in the mines and the associated

activities be planned to have the minimum possible intensity and impact on the

wild life in the surrounding area.

Control of the Impacts:- Land

Minimized

by planning surface layout of the mining areas and optimizing the land

requirement for the various uses.

Design of land reclamation development of the post mining

land use.

Control of the Impacts:- Water

It

is necessary to plan the mining and associated activities in such a manner that

their impacts on the water regime are minimum.

Control of the Impacts:- Air

Use

of dust extractors with the drill machines

By

optimizing the blast design .

Proper

maintenance of the roads .

Water spraying at the transfer points tends to

reduce air pollution.

Enclosing

the mineral handling and preparation units .

Proper

maintenance of the equipment and machines in the mines.

The

locations of the residential locations should be planned such that they are on

the up wind side .

Green belts of adequate widths, say 25 -50 m, may be

planned between the residential areas and the mines.

CMR1[191. Use, Supply maintenance of protective footwear.

– (1) No person shall go into, or work in, or be allowed to go into, or work

in, a mine, unless he wears a protective footwear of such type as may be

approved by the Chief Inspector by a general or special order in writing.

(2) The protective footwear referred to in sub-regulation

(1) shall be supplied free of charge, at intervals not exceeding six months, by

the owner, agent or manager of a mine who shall at all times maintain a

sufficient stock of protective footwear in order to ensure immediate supply

as and when need for the same arises.

(3) Where a footwear is provided otherwise than as

aforesaid, the supply shall be made on payment of full cost.

(4) The owner, agent of manager of a mine shall provide

at suitable places in the mine dubbing and revolving brushes or make other

suitable alternative arrangements for the cleaning of protective footwear by

the persons using them. It shall however be the

responsibility of the person supplied with the protective

footwear to arrange the repair of the same at his own cost.

CMR 191A. Use and supply of helmet.

(1) No person shall go into, or work, in or be allowed to

go into or work in, a mine, other than the precincts of a mine occupied by an

office building,canteen, creche, rest shelter, first aid room or any other

building of a similar type, unless he wears a helmet of such type as may be

approved by the Chief Inspector by a general or special order in writing :

Provided that where the Chief Inspector is of the opinion that due to special

circumstances it is not necessary of

reasonably practicable for any person or class of persons going into, or

working in, a mine to wear a helmet, he may, by a general or special order in

writing and subject to such conditions as he may specify therein, exempt such

person or class of

persons, from the operation of the provisions of this

sub-regulation.

(2) The helmet referred to in sub-regulation(1) shall be

supplied free of charge, at intervals not exceeding three years or such other

interval as the Chief Inspector may specify by a general or special order in

writing by the owner, agent or manager of a mine, who shall at all times

maintain a sufficient stock thereof in order to ensure immediate supply as and

when need for the same arises : Provided that when a helmet is accidentally

damaged during legitimate use, the owner, agent or manager shall immediately

replace the damaged helmet free of cost.

(3) Where a helmet is provided otherwise than as

aforesaid, the supply shall be made on

payment of full cost.

191B. Supply of other protective equipment. –

(1) Where is appears to the Regional Inspector or the

Chief Inspector that any person or class of persons employed in a mine is

exposed to undue hazard by reason of the nature of his employment, he may, by a

general or special order in writing, require the owner, agent or manager of the

mine to supply to such person or class of persons, free of charge, gloves,

goggles, shinguards, or such other protective equipment as may be specified in

the order.

(2) The protective equipment provided under

sub-regulation(1) shall be replaced free of charge by the owner, agent or

manager whenever it is rendered unserviceable by legitimate use. In any other

event, the replacement shall be made on payment of full cost.

(3) If any dispute arises as to the life of any

protective equipment, it shall be referred to the Chief Inspector for decision.

Comments

Post a Comment